The City of Farmington Hills is the second largest city in Oakland County with a population of over 80,000. Most of the city has excellent water pressure and adequate fire protection but as the name suggests, the hilly terrain presents some pressure challenges in certain areas. With roughly 468 miles in their water distribution system, the city uses an average of 8.6 MGD from the Detroit Water and Sewerage Department (DWSD). DWSD offers reduced rates for communities that can reduce their maximum day and/or peak hour demands. While the city’s average daily consumption is good, their peak hour factor of 4.4 and maximum day of 21 MGD comes at a high cost.

OHM Advisors, an integrated engineering, architecture and planning firm were brought in to identify areas of concern and develop a long-term water system sustainability plan. In the process they identified nine areas that had pressure concerns. When pressure is too high, leakage rates go up and when it is too low, fire protection is compromised.

“It was critical that these areas be addressed first,” said Jody Caldwell, Chief Engineer for Oakland County Water Resource Commission. The desired operating pressure for a water system is 50-80 psi, with the state required minimum normal working pressure of 35 psi. To ensure fire protection, the required minimum is 20 psi during emergencies. In order to hit these targets, Kennedy Industries suggested two styles of pressure reducing valves (PRV) to be installed in five different points in the distribution system, ranging in size from 6” to 24”.

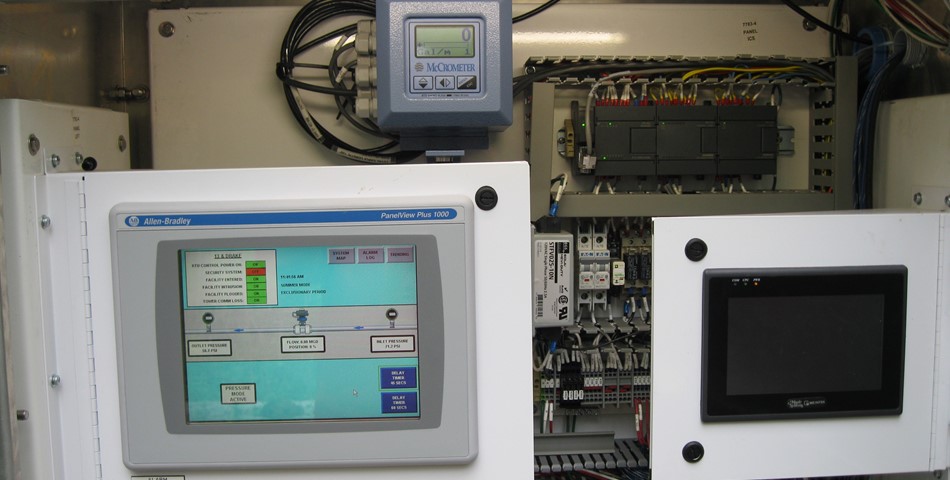

The first type of PRV was Singer’s S106-2SC-PCO-PR-SC-SPI-MV. This model of valve provides for remote SCADA control of flow and pressure. In the event there is a loss of power or SCADA control, there is a pressure reducing override that will take over, ensuring pressure is maintained through the system. Oakland County and OHM also wanted the valve to have the ability to be fully open in the event of low pressure differential across the valve.

The valve-opening pilot on the low inlet pressure setting ensures that the valve can go to a full open position on low inlet pressure to maintain fire flow and operating pressures in the system. The valve was additionally fitted with upstream and downstream pressure transducers also tied into SCADA to provide for this functionality.

The second type of PRV implemented in the system was a Singer’s S106-2PR-SC-SPI-MV. This valve is equipped with two pressure reducing Model 160 pilot controls with different set points. Through SCADA control, Oakland County has the ability to select which pressure reducing set point they would like the system maintained at. In addition the ability to lower the pressure in off peak usage time, typically nighttime hours and non-summer conditions, has reduced the utilities non-revenue water loss and pipe breakage.

All valves have the SPI-MV, single point electromagnetic flow meter that is built right into the valve and guarantees an accuracy of 2 percent of reading throughout the specified velocity range. This enables Oakland County to measure flow into each of the corresponding pressure zones, track usage and detect pipe breakage. It also allows the county to control & regulate the flow from their supplier, DWSD, during the peak flow hours.

Furthermore it allows the city to fill their tank at off peak hours and then control the total draw/flow by reducing flow to districts as needed. “The valves have exceeded the County’s expectations by allowing them to smoothly & effortlessly control flow rates within a 20 GPM dead band,” said Carrie Cox, Assistant Chief Engineer for Oakland County. It was also realized that with the construction of the 3 million gallon storage tank and accompanying controls, the peak demands on DWSD could be reduced resulting in an annual savings of USD3,300.

An added benefit of the control system is that with an elevated storage tank in the City’s Northwest District they can automatically feed over half the city in the event of an emergency or loss of water supply from DWSD. This fall DWSD had a power issue at a nearby facility that is the main feed into the City. Working together, the control valves and storage tank continued to provide the desired water pressure to the city’s customers. Residents did not notice any pressure changes even though DWSD supply pressures were as low as 20 psi.

The seamless operations of the five control valves averted a situation that before their installation could have resulted in a system wide precautionary boil water advisory. “We received several low supply pressure alarms yet our system’s pressure barely changed. We were glad we had the storage tank and control valves on this morning,” said Dave Brown, Pump Maintenance Supervisor II for Oakland County. The results have already been very successful. The ability to tightly control usage has allowed Oakland County to renegotiate their rates from their supplier providing them with an annual rate savings of USD3.3 Million. The USD16 million project is projected to pay for itself in 6-7 years.